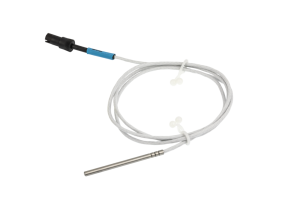

Smart DS – Temperature Sensor

Dickson’s temperature Smart-DS Sensor offers an innovative and convenient solution for monitoring temperature in a wide variety of applications where accuracy is critical. This robust metal-tipped sensor

continually measures temperature so you can keep a close eye on the environmental conditions affecting your valuable assets.

Related Blog Posts

Dickson Replaceable Sensors™ 101

With such a wide selection of data loggers and can be difficult finding the right Dickson Replaceable Sensor. Read more about our replaceable sensor data loggers.

Temperature sensors… and much more!

Temperature monitoring is key to the production, storage, transportation, and use of your most sensitive products. But we know that to meet your safety and quality standards, you often need to monitor many other physical parameters: humidity, pressure, CO2, light, and more. To simplify your processes and allow you to focus on the essentials, Dickson has created a range of robust, accurate, versatile sensors that comply with the strictest standards in force worldwide. Whether you are active in the pharmaceutical industry, healthcare, scientific research, transportation, logistics, aerospace, or food processing, Dickson offers you the monitoring system best suited to your needs. Connect our Data Loggers to one or more external probes as needed and monitor the environmental parameters of your refrigerators, freezers, incubators, warehouses, clean rooms, controlled temperature transport, and more, 24/7.

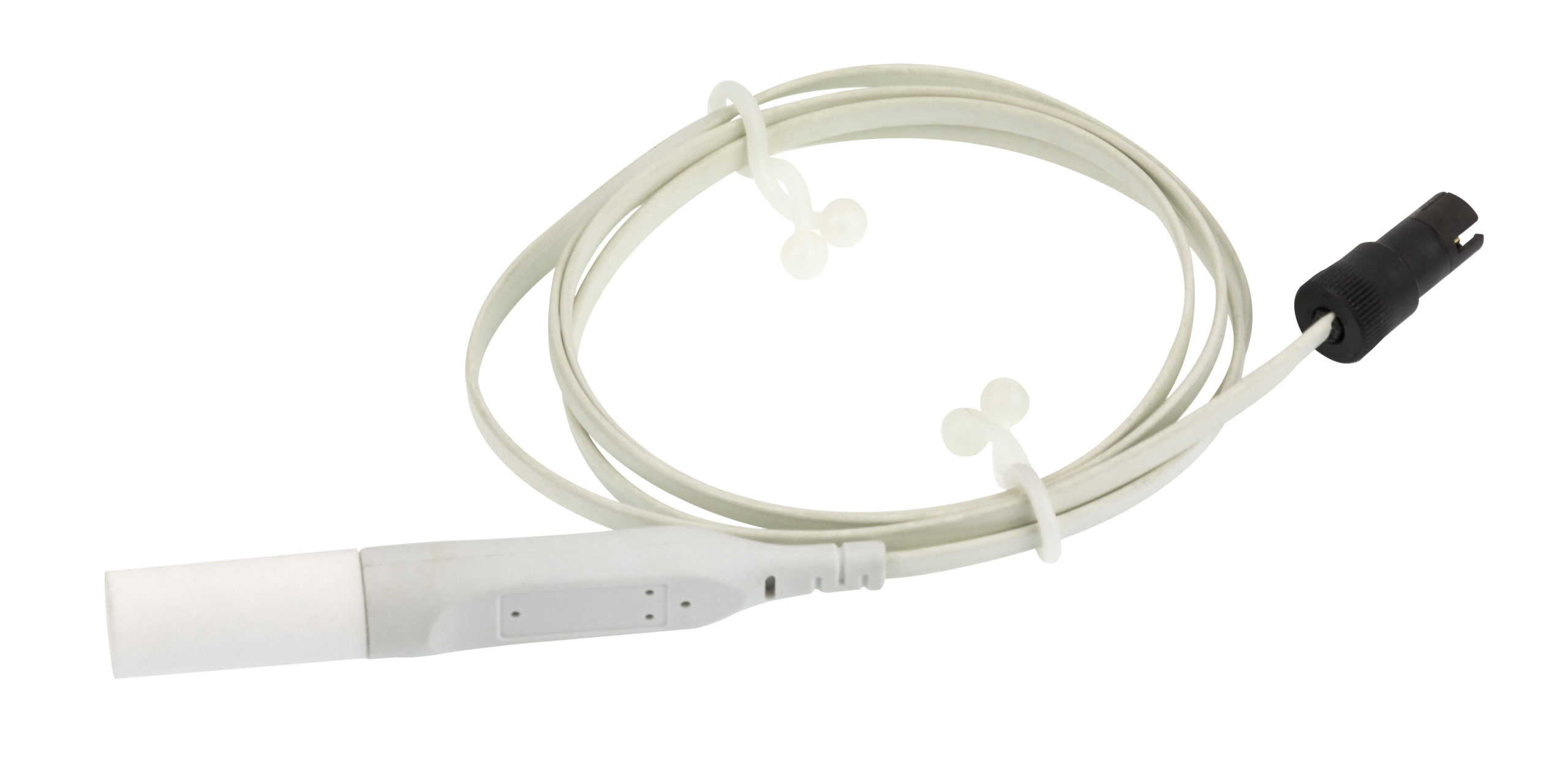

Smart sensors that simplify environmental monitoring

Dickson’s temperature and other physical parameter sensors benefit from our extensive expertise in environmental monitoring and advanced technology. Our Smart Sensors are among the most efficient on the market. With their patented technology, they embed calibration data to provide reliable and accurate readings of your environmental parameters at any time. Several versions of our Smart Sensors are available to meet your needs simply and effectively: temperature, temperature + humidity, and even our latest innovation: the Triple Smart Sensor for Temperature, Humidity and CO2. The Triple Smart Sensor was designed specifically for CO2 incubator monitoring. Coupled with our Cobalt X Data Logger, this intelligent probe — the most compact and complete on the market — continuously measures temperature, humidity, and carbon dioxide concentration inside incubators to ensure stable conditions and optimal control of the culture environment.

Accurately calibrated temperature sensors

For decades, Dickson has specialized in compliance solutions. Because we know that you must meet strict standards and regulations, we have implemented manufacturing, installation, and control processes that leave no room for improvisation. The same goes for the calibration of our probes and sensors. Our calibration laboratories are accredited to ISO/IEC 17025 A2LA and NIST traceable standards, guaranteeing calibration in accordance with the highest compliance chains and precisely reflecting your environment. Better yet, to ensure continuous monitoring of your environmental parameters, our Smart Sensors store calibration data provided by our laboratories. If a change is necessary, simply replace one sensor with another without having to shut down or disconnect your monitoring system.

Temperature Sensors

Temperature monitoring is our speciality. Our temperature sensors provide you with real-time measurements. Connected to our data loggers, they give you peace of mind and rigorous precision, detecting the slightest variation or temperature excursion to avoid any loss of sensitive products.

Humidity Sensors

Our humidity sensors comply with the most stringent standards, enabling you to measure humidity conditions in your critical environments in real time.

CO2 Sensors

Discover our range of CO2 sensors designed to help you maintain the optimum conditions required by your industry standards.

Differential Pressure Sensors

Our differential pressure transducers are designed to meet your most complex monitoring needs, measuring the pressure difference between two zones, such as a high-pressure cleanroom and “regular” room or hallway

Absolute Pressure Sensors

If you need precise, rigorous absolute pressure monitoring, you can rely on our expertise. Our sensors are designed to meet the most stringent requirements of your industry

Dry Contact Sensors

Our dry contact sensor is designed to monitor equipment providing dry contact output (door opening-closing, uninterruptible power supplies, air conditioning units, ultra-low-temperature freezers). Connects to Cobalt X 2.5 mm jack input.

Universal Sensors

The Universal Smart-Sensor measures electrical current from industry standard equipment with 4-20 mA, 0-5 V, or 0-10 V output. Features Smart-Sensor technology, with on-board calibration details and for easy calibration.

A wide range of sensors and probes

Dickson offers a wide range of sensors and probes capable of monitoring a large variety of environmental parameters, far beyond just temperature and humidity. Our solutions include specialized sensors for measuring pressure, CO2, light, and more. This diversity allows our clients to configure complete monitoring systems tailored to their specific needs. Whether for applications in pharmaceutical laboratories, medical research, or refrigerated warehouses, our sensors ensure optimal accuracy.

Moreover, our sensors are designed to function in extreme conditions, whether at very high or very low temperatures. For example, our cryogenic temperature sensors are essential for monitoring freezers at -80°C used for storing vaccines and biological samples. Conversely, our high-temperature sensors are perfect for industrial environments such as ovens or incubators requiring strictly controlled conditions. With this flexibility and diversity, Dickson meets the requirements of the most demanding sectors, such as aerospace, scientific research, and logistics, ensuring continuous and reliable monitoring of all critical parameters.

Frequently Asked Questions

What are Dickson’s replaceable temperature sensors?

+Dickson offers a range of replaceable sensors designed for easy recalibration and maintenance. These sensors, such as the Ambient Temperature Sensor (RTMP) and the Temperature & Humidity Sensor (RTRH-R), can be swapped out without interrupting monitoring processes, ensuring continuous and accurate data collection.

What are relative humidity sensors?

+Relative humidity (RH) sensors measure the amount of water vapor present in the air relative to the maximum amount the air can hold at a given temperature. This measurement is expressed as a percentage, indicating how close the air is to saturation.

Where are temperature sensors mostly used?

+Temperature sensors are utilized across various industries, including:

- Pharmaceuticals: Monitoring storage conditions for drugs and vaccines.

- Hospitals and Healthcare: Maintaining appropriate temperatures in medical equipment and patient care areas.

- Third-Party Logistics: Ensuring the highest product quality and safety throughout the supply chain.

- Food and Beverage: Ensuring proper storage and processing temperatures.

- Manufacturing: Controlling processes that are temperature-sensitive.

- Aerospace: Monitoring environmental conditions for equipment and materials.

How does a relative humidity sensor work?

+RH sensors usually operate using capacitive or resistive methods. For capacitive sensors, they have a hygroscopic dielectric material between two conductive plates. As humidity changes, the dielectric constant of the material changes, altering the capacitance, which is measured and converted into an RH value. For resistive sensors, they use materials whose electrical resistance varies with humidity. As moisture levels change, the resistance changes, and this variation is measured to determine RH.

How do I choose the right temperature sensor for my application?

+Selecting the appropriate temperature sensor involves considering factors such as:

- Temperature range: Ensure the sensor operates effectively within your required temperature limits.

- Accuracy: Determine the level of precision necessary for your application.

- Environment: Consider conditions like humidity, pressure, and potential exposure to chemicals.

- Response time: Assess how quickly the sensor needs to detect temperature changes.

- Calibration requirements: Understand the calibration needs to maintain accuracy over time.

What are the different types of humidity sensors?

+The primary types of humidity sensors include: Capacitive sensors, resistive sensors, and thermal conductivity sensors. Capacitive sensors are known for their accuracy and stability over a wide humidity range; resistive sensors are often used in applications where cost is a concern, though they may be less accurate than capacitive types; and thermal conductivity sensors measure absolute humidity by assessing the thermal conductivity of the air, which changes with moisture content.

What maintenance tips should I follow for temperature sensors?

+To maintain optimal performance of temperature sensors:

- Regular calibration: Schedule periodic calibrations to ensure accuracy.

- Proper handling: Avoid physical shocks and exposure to harmful substances.

- Environmental protection: Use appropriate enclosures if the sensor is in harsh conditions.

- Routine inspections: Check for signs of wear, corrosion, or damage.

In which cases are relative humidity sensors used?

+RH sensors are utilized in various applications, including: HVAC systems, industrial processes, storage facilities, laboratories and incubators.

How often do I need to calibrate my temperature sensors?

+Calibration frequency depends on factors like sensor type, application criticality, and manufacturer recommendations. Generally, it’s advisable to calibrate temperature sensors annually. However, for applications requiring high precision, more frequent calibrations may be necessary. Consulting with the sensor manufacturer or a calibration specialist can provide guidance tailored to your specific needs.

How do I choose the right sensor for my application?

+As you look for a humidity sensor for your use-case, consider the following factors:

- Measurement Range and Accuracy: Ensure the sensor covers the humidity range you need and provides the accuracy required for your application.

- Environmental Conditions: Consider the environment where the sensor will be used, such as temperature extremes, exposure to chemicals, or outdoor conditions, and choose a sensor that can withstand these factors.

- Calibration Needs: Determine how often the sensor requires calibration to maintain accuracy and if this fits within your maintenance capabilities.

- Integration: Check how easily the sensor can be integrated into your existing systems, including compatibility with other devices and software.

By evaluating these aspects, you can select a humidity sensor that best fits your specific needs.

Are Dickson’s temperature sensors compatible with cloud-based monitoring systems for real-time data access?

+Yes, our temperature sensors are compatible with their cloud-based monitoring systems, enabling real-time data access and alerts. Pair the sensors with wireless data loggers and cloud software to monitor environmental conditions remotely. This integration allows for centralized data management, compliance reporting, and proactive issue detection, ideal for critical industries like healthcare and pharmaceuticals.

Can I install a replacement sensor like this myself, or do I need professional assistance?

+Many RH sensors can be installed by the user without professional assistance. For instance, our plug and play Smart-Sensors and replaceable sensors store calibration data on-board, allowing for easy swapping and calibration.

How to install and set up Dickson’s temperature sensors for continuous monitoring?

+Our temperature sensors are designed for straightforward and easy installation and integration with monitoring systems. Simply connect the sensor to your device, configure the settings via our software, and begin tracking data. Detailed instructions and technical support are available to ensure a seamless setup, even for first-time users or complex monitoring environments.

How accurate are Dickson’s relative humidity sensors?

+Dickson’s RH sensors offer high accuracy. For example, the Temperature & Humidity Sensor (RTRH-R) provides an accuracy of ±2.0% RH from 5.0 to 95.0% RH.

How do I know if I’ve selected the right temperature sensor for my device?

+To ensure you’ve selected the correct temperature sensor, check the specifications and compatibility details in your device’s user manual or on the product page. Look for matching model numbers, measurement ranges, and connector types. If you’re uncertain, contact customer support for guidance, providing your device’s model information to confirm compatibility.

How do I calibrate a relative humidity sensor?

+Calibration involves comparing the sensor’s readings to a known standard and adjusting as necessary. Dickson offers A2LA and NIST-traceable calibration services to ensure sensor accuracy. Some sensors, like Dickson’s Smart-Sensors, store calibration data on-board, simplifying the calibration process.

How frequently should relative humidity sensors be recalibrated?

+Recalibration frequency depends on usage and environmental conditions. For critical applications, annual calibration is recommended. Dickson provides calibration services to maintain sensor accuracy.

What factors can affect the accuracy of these sensors?

+There are several factors that can affect the accuracy of your sensors, including: exposure to contaminants, extreme temperature fluctuations, and mechanical stress.

Are there storage or handling requirements for these specific sensors?

+Yes, proper storage and handling are crucial. We recommend: Keeping sensors in a clean, dry environment within specified temperature and humidity ranges; avoiding exposure to contaminants and physical shocks; and storing sensors with their calibration data to ensure accuracy upon deployment.

Which data logger should I choose with these sensors?

+The choice depends on your specific needs:

What are temperature sensors?

+Temperature sensors are devices that measure the degree of hotness or coldness in an environment and convert this information into electronic data for monitoring, recording, or signaling temperature changes.

How do temperature sensors work?

+Temperature sensors operate by detecting changes in physical properties—such as resistance, voltage, or current—that vary with temperature. These variations are then converted into readable data, allowing for accurate temperature monitoring.

What are the different types of temperature sensors?

+Common types of temperature sensors include:

- Thermocouples: Made by joining two dissimilar metals, they generate a voltage proportional to temperature differences.

- Resistance Temperature Detectors (RTDs): Utilize the principle that a metal’s resistance changes with temperature; platinum is commonly used for its stability.

- Thermistors: Composed of ceramic or polymer materials, they exhibit significant resistance changes with temperature variations.

- Semiconductor-based sensors: Integrated circuits that measure temperature by monitoring voltage changes across a diode.