Humidity Sensors for Protecting Moisture-Sensitive Inventory

Dickson humidity sensors, also called humidity meters, hygrometers and thermohygrometers, are designed for measuring, monitoring and mapping humidity levels across various applications and industries.

Once integrated with Dickson chart recorders, or data loggers and temperature monitoring software, our humidity sensors allow you to record and view humidity data in real time to help ensure environments stay within specified humidity ranges—a critical requirement for safety and compliance in healthcare facilities, pharmaceuticals, food storage and more. Made for high accuracy and durability, our ambient and relative humidity sensors can help you maintain quality standards while protecting sensitive materials from moisture-related damage.

Related Blog Posts

Why Should Pharmacies Use Cold Storage Monitoring?

An increasing number of drugs require refrigerated or frozen storage. In this article, we’ll talk about how this affects pharmacies, and how modern temperature monitoring systems can make pharmacy operations more reliable and efficient.

Cloud-based Temperature and Environmental Monitoring for Healthcare: An Inside Look

Environmental monitoring is a critical part of healthcare facility operations. In this article, we’ll cover the use of modern cloud-based systems in this area.

Temperature, Humidity, Pressure & Voltage: A Guide to Data Logger Functions

Data loggers are commonly used to measure temperature, humidity, pressure, and voltage. Here we’ll discuss why these functions are important.

The Dickson Difference: Why Quality Humidity Sensors Matter

Don’t let humidity lead to product loss or compromise your compliance records. Dickson humidity sensors and probes are your first line of defense, providing accurate readings to keep moisture-sensitive items safe and your operation compliant. When paired with Dickson data loggers and DicksonOne software, our probes and sensors offer a complete 24/7 monitoring system that sends alert notifications when there is a notable excursion so you can promptly take action.

Sensor Calibration Meeting the Highest Industry Standards

Calibration services from Dickson provide you with the added peace of mind that your humidity sensors are consistently operating with exceptional accuracy.

- Decades of experience in temperature and humidity mapping, sensor installation and validation

- ISO/IEC 17025 accredited by the American Association for Laboratory Accreditation (A2LA)

- Engineers and technicians trained in National Institute of Standards and Technology (NIST) traceable standards

Calibrating your humidity sensors at least once a year is best practice, however the precise frequency varies greatly depending on its application. Learn more about Dickson’s calibration services and get guidance on your specific application from our experts.

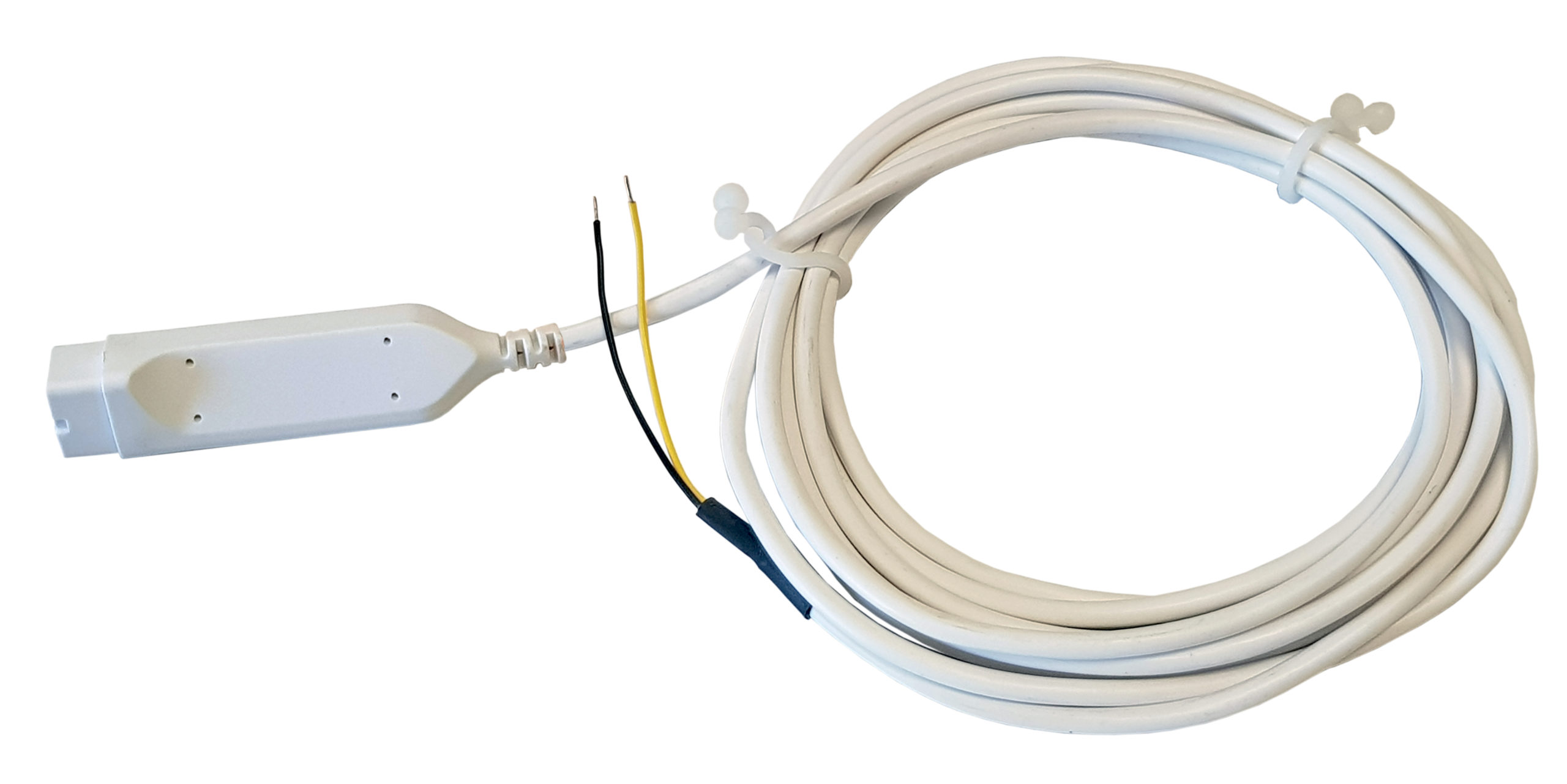

Speed Up Recalibration Time With Plug-and-Play Replaceable Sensors

Recalibrating your equipment just got simpler. With Dickson Replaceable Sensors™,you can receive pre-calibrated sensors and swap them easily.

4 Keys to Choosing Humidity Sensors for Your Application

- Find the Correct Sensor Type: There are three basic types of humidity sensors:

Capacitive sensors measure relative humidity and are known for high accuracy over a wide range.

Resistive sensors measure relative humidity and are less accurate than capacitive sensors. They are often used in applications where cost is an overriding concern.

Thermal conductivity sensors measure absolute humidity and are used when precise moisture control is critical.

- Select for Accuracy: Look for sensors or hygrometers with high accuracy and a low margin of error. Accuracy in humidity sensors is typically expressed as a percentage of the reading, plus or minus a certain value.

For example, a sensor with an accuracy of ±2% RH means that the measured reading could be off by 2% above or below the actual humidity level. A ±2% RH is generally considered highly accurate and suitable for applications in pharmaceutical manufacturing and storage, calibration laboratories, food processing and storage and semiconductor manufacturing.

- Pay Attention to Response Time: The response time of the sensor refers to how quickly it reacts to changes in humidity levels. The average response time for humidity sensors is between 5-30 seconds.

Faster response times are essential in applications where rapid changes need to be detected and addressed promptly. Consider the required response time for your application and choose a sensor that meets those requirements.

- Consider Environmental Factors: The environment in which the sensor will be used can affect its performance and lifespan. Consider factors such as temperature, pressure and the presence of contaminants or corrosive elements. Choose a humidity sensor that is designed to withstand the specific environmental conditions of your application.

Want More Information About Dickson Humidity Sensors?

If you have any questions about finding the right humidity sensor for your application, please contact an expert at Dickson.

All Sensors

Temperature Sensors

CO2 Sensors

Differential Pressure Sensors

Absolute Pressure Sensors

Dry Contact Sensors

Universal Sensors

Frequently Asked Questions

Which data logger should I choose with these sensors?

+The choice depends on your specific needs:

What are relative humidity sensors?

+Relative humidity (RH) sensors measure the amount of water vapor present in the air relative to the maximum amount the air can hold at a given temperature. This measurement is expressed as a percentage, indicating how close the air is to saturation.

How does a relative humidity sensor work?

+RH sensors usually operate using capacitive or resistive methods. For capacitive sensors, they have a hygroscopic dielectric material between two conductive plates. As humidity changes, the dielectric constant of the material changes, altering the capacitance, which is measured and converted into an RH value. For resistive sensors, they use materials whose electrical resistance varies with humidity. As moisture levels change, the resistance changes, and this variation is measured to determine RH.

What are the different types of humidity sensors?

+The primary types of humidity sensors include: Capacitive sensors, resistive sensors, and thermal conductivity sensors. Capacitive sensors are known for their accuracy and stability over a wide humidity range; resistive sensors are often used in applications where cost is a concern, though they may be less accurate than capacitive types; and thermal conductivity sensors measure absolute humidity by assessing the thermal conductivity of the air, which changes with moisture content.

In which cases are relative humidity sensors used?

+RH sensors are utilized in various applications, including: HVAC systems, industrial processes, storage facilities, laboratories and incubators.

How do I choose the right sensor for my application?

+As you look for a humidity sensor for your use-case, consider the following factors:

- Measurement Range and Accuracy: Ensure the sensor covers the humidity range you need and provides the accuracy required for your application.

- Environmental Conditions: Consider the environment where the sensor will be used, such as temperature extremes, exposure to chemicals, or outdoor conditions, and choose a sensor that can withstand these factors.

- Calibration Needs: Determine how often the sensor requires calibration to maintain accuracy and if this fits within your maintenance capabilities.

- Integration: Check how easily the sensor can be integrated into your existing systems, including compatibility with other devices and software.

By evaluating these aspects, you can select a humidity sensor that best fits your specific needs.

Can I install a replacement sensor like this myself, or do I need professional assistance?

+Many RH sensors can be installed by the user without professional assistance. For instance, our plug and play Smart-Sensors and replaceable sensors store calibration data on-board, allowing for easy swapping and calibration.

How accurate are Dickson’s relative humidity sensors?

+Dickson’s RH sensors offer high accuracy. For example, the Temperature & Humidity Sensor (RTRH-R) provides an accuracy of ±2.0% RH from 5.0 to 95.0% RH.

How do I calibrate a relative humidity sensor?

+Calibration involves comparing the sensor’s readings to a known standard and adjusting as necessary. Dickson offers A2LA and NIST-traceable calibration services to ensure sensor accuracy. Some sensors, like Dickson’s Smart-Sensors, store calibration data on-board, simplifying the calibration process.

How frequently should relative humidity sensors be recalibrated?

+Recalibration frequency depends on usage and environmental conditions. For critical applications, annual calibration is recommended. Dickson provides calibration services to maintain sensor accuracy.

What factors can affect the accuracy of these sensors?

+There are several factors that can affect the accuracy of your sensors, including: exposure to contaminants, extreme temperature fluctuations, and mechanical stress.

Are there storage or handling requirements for these specific sensors?

+Yes, proper storage and handling are crucial. We recommend: Keeping sensors in a clean, dry environment within specified temperature and humidity ranges; avoiding exposure to contaminants and physical shocks; and storing sensors with their calibration data to ensure accuracy upon deployment.